- Tel: +86-531-88897198

- [email protected]

Versatile High-Purity Solvent for Pharmaceutical Intermediates & Industrial Reactions

|

Parameter

|

Specification

|

|---|---|

|

Chemical Name |

4-Methylmorpholine |

|

CAS Number |

109-02-4 |

|

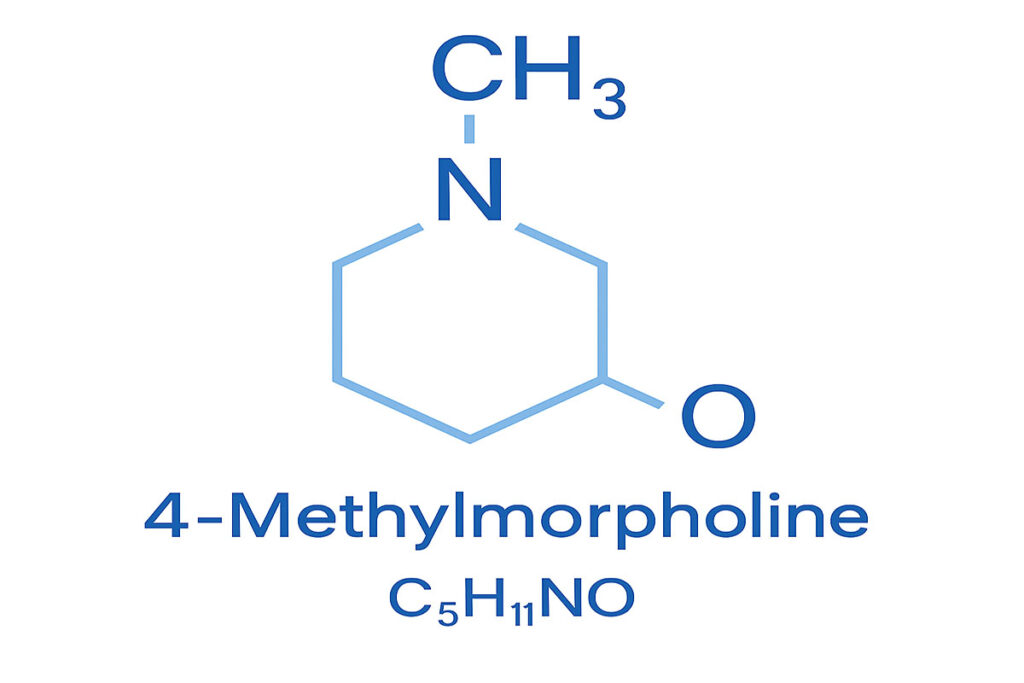

Molecular Formula |

C₅H₁₁NO |

|

Molecular Weight |

101.15 g/mol |

|

Purity |

≥99.0% (GC) |

|

Appearance |

Colorless to slightly yellow transparent liquid |

EXCELLENT SOLVENT POWER FOR APIs & EPOXIES

LOW MOISTURE & AMINE CONTENT ASSURED

BULK TANK & LAB PACK OPTIONS AVAILABLE

TUODA’s 4-Methylmorpholine is a premium-grade cyclic amine widely used as a solvent and intermediate in pharmaceuticals, agrochemicals, and epoxy resin systems.

With ≥99.0% purity and excellent moisture control, it ensures stable performance across demanding synthesis conditions.

4-Methylmorpholine (CAS 109-02-4) is a critical building block in high-value chemical synthesis, especially in isocyanate catalyst systems, peptide intermediates, and fine chemical applications requiring tight moisture control.

TUODA’s 4-Methylmorpholine is manufactured in GMP-compliant facilities using advanced distillation technology to ensure ultra-low impurity levels and minimal volatility drift. Each batch is sealed under nitrogen and validated with full COA/TDS documentation to support reliable global supply, regulatory compliance, and sensitive synthesis needs.

Industry-Leading Quality Parameters for High-Purity 4-Methylmorpholine

All specifications above are strictly validated through comprehensive quality assurance testing. Customized specifications and detailed documentation are available upon request.

Why TUODA’s 4-Methylmorpholine Sets the Industry Standard

Pharmaceutical-grade purity ≥99.0%, ensuring reliable reaction outcomes and minimizing unwanted by-products across sensitive systems.

Stabilized formulation prevents degradation during storage and shipping, delivering performance reliability across varied conditions.

Performs as a highly selective solvent and intermediate in synthesis, boosting yield, purity, and downstream reaction control.

With over a decade of fine chemical experience, TUODA’s technical team offers full-cycle support for safe, scalable use of 4-Methylmorpholine.

Experience the confidence of working with TUODA’s high-purity 4-Methylmorpholine in your daily production.

4-Methylmorpholine's Versatile Role in Modern Industrial Processes

Essential catalyst and base in API manufacturing, facilitating critical reactions including acylations, alkylations, and condensations while providing superior selectivity and yield improvement.

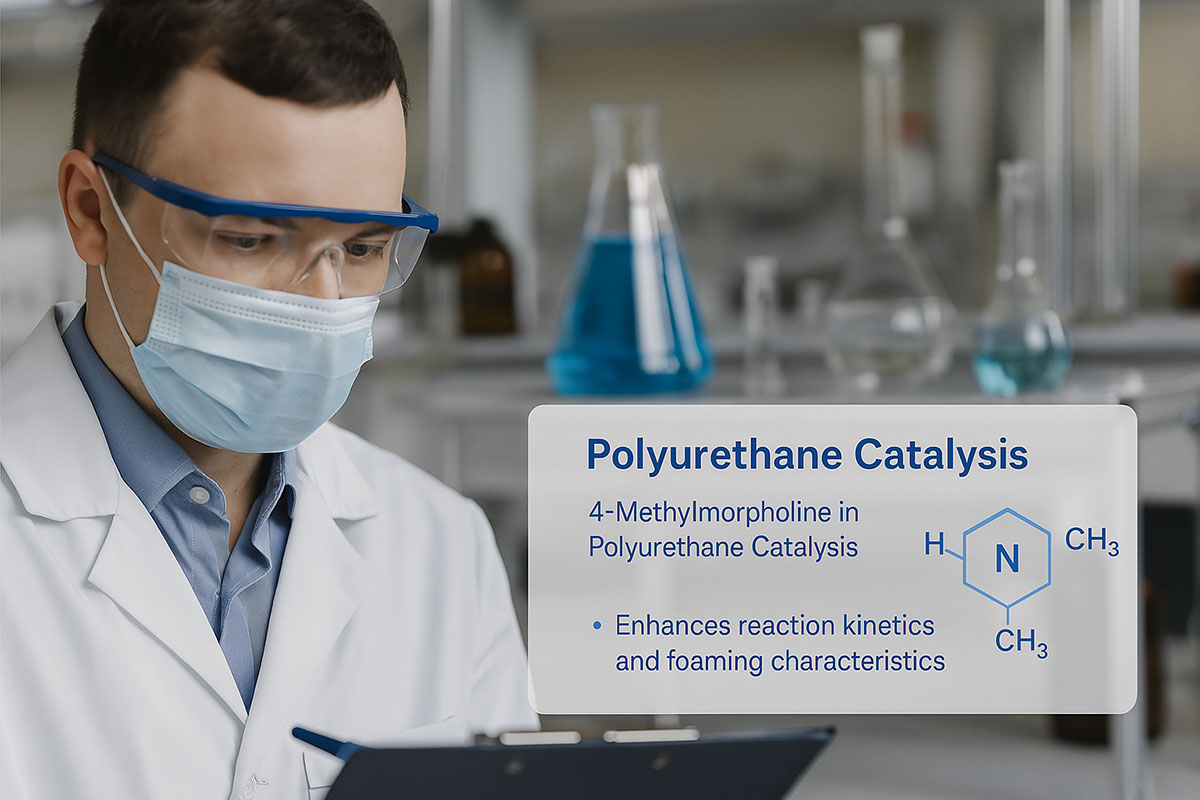

High-performance catalyst for polyurethane foam production, providing precise control over reaction kinetics, cell structure, and final product properties in flexible and rigid foam applications.

Effective absorbent for carbon dioxide capture systems, offering rapid absorption kinetics, high loading capacity, and excellent regeneration properties for industrial emission reduction applications.

Versatile reagent in fine chemical synthesis, functioning as a mild base, nucleophilic catalyst, and formaldehyde scavenger for producing high-value specialty chemicals with enhanced purity.

Key formulation component in high-performance coatings and adhesives, providing improved curing profiles, enhanced adhesion properties, and superior resistance to environmental factors.

Indispensable laboratory reagent for organic synthesis methodology development, serving as a versatile base, catalyst, and solvent in academic and industrial research applications.

4-Methylmorpholine stands as a cornerstone reagent in modern pharmaceutical synthesis, offering exceptional versatility as a mild organic base and catalyst for numerous critical transformations in API manufacturing.

Our pharmaceutical-grade 4-methylmorpholine delivers exceptional purity and batch-to-batch consistency, meeting the stringent requirements for validated pharmaceutical processes while minimizing impurity profiles in final APIs.

A leading pharmaceutical manufacturer implemented TUODA's 4-methylmorpholine in their GMP synthesis of a complex peptide-based API, achieving 94% coupling efficiency (compared to 78% with traditional methods) while reducing racemization by-products to below 0.1%, significantly enhancing product quality and process economics.

4-Methylmorpholine functions as a highly effective catalyst in polyurethane foam production, providing precise control over reaction kinetics and enabling manufacturers to achieve optimal foam properties for diverse applications.

Our technical-grade 4-methylmorpholine delivers consistent catalytic performance across production batches, ensuring reproducible foam properties essential for high-volume manufacturing operations.

A major automotive component supplier incorporated our 4-methylmorpholine catalyst in their high-resilience foam formulation, achieving 22% faster demold times while maintaining excellent compression set resistance and durability, enabling significant production throughput improvements and energy savings.

4-Methylmorpholine represents an important component in advanced carbon dioxide capture systems, offering a compelling combination of rapid absorption kinetics, high loading capacity, and excellent regeneration properties.

Our high-purity 4-methylmorpholine demonstrates excellent thermal and oxidative stability in carbon capture applications, maintaining performance through numerous absorption-regeneration cycles while minimizing solvent degradation.

A cement manufacturer implemented our 4-methylmorpholine in their carbon capture system, achieving 92% CO₂ removal efficiency with 35% lower regeneration energy requirements compared to conventional amine systems, significantly improving the economic viability of their carbon reduction strategy.

4-Methylmorpholine serves as a versatile reagent in fine chemical synthesis, functioning as a mild base, nucleophilic catalyst, and formaldehyde scavenger for producing high-value specialty chemicals with enhanced purity profiles.

Our ultra-high purity 4-methylmorpholine enables consistent reaction performance and reproducible product quality, critical factors in the production of high-value specialty chemicals with stringent specifications.

A specialty electronic materials producer implemented our 4-methylmorpholine in their synthesis of a critical semiconductor precursor, achieving 99.8% purity with metal contamination below 10 ppb, enabling next-generation device performance while improving manufacturing yield by 18%.

4-Methylmorpholine plays a crucial role in advanced coating and adhesive formulations, providing improved curing profiles, enhanced adhesion properties, and superior resistance to environmental factors.

Our industrial-grade 4-methylmorpholine delivers reliable performance in coating and adhesive applications, with the consistency required for reproducible curing behavior and final product properties.

A protective coatings manufacturer incorporated our 4-methylmorpholine into their two-component polyurethane system for infrastructure applications, achieving 40% faster cure times even in high-humidity environments while maintaining excellent chemical resistance and weatherability, significantly reducing application constraints.

4-Methylmorpholine stands as an indispensable laboratory reagent for organic synthesis methodology development, serving as a versatile base, catalyst, and solvent in academic and industrial research applications.

We offer research-grade 4-methylmorpholine in various package sizes suitable for laboratory use, with comprehensive analytical documentation and technical support for research applications.

A university research group utilized our high-purity 4-methylmorpholine to develop a novel flow chemistry protocol for continuous amide bond formation, achieving 95% yields with minimal waste generation and significantly reduced solvent usage, leading to a patent application and subsequent technology transfer to the pharmaceutical industry.

Discover how our high-purity 4-Methylmorpholine can enhance your specific application

Industry-Leading Quality Parameters for 4-Methylmorpholine with Exceptional Purity and Consistency

| Chemical Formula: | C₅H₁₁NO |

| Molecular Weight: | 101.15 g/mol |

| CAS Number: | 109-02-4 |

|

Parameter

|

Standard Grade

|

High-Purity Grade

|

Ultra-Pure Grade

|

|---|---|---|---|

|

Content |

≥ 98.0% |

≥ 99.0% |

≥ 99.5% |

|

Water Content |

≤ 0.5% |

≤ 0.2% |

≤ 0.05% |

|

Residual Amine Base |

≤ 1.0% |

≤ 0.5% |

≤ 0.1% |

|

Peroxide Impurities |

≤ 100 ppm |

≤ 50 ppm |

≤ 10 ppm |

|

Total Impurities |

≤ 1.5% |

≤ 0.7% |

≤ 0.3% |

|

Property

|

Value

|

|---|---|

|

Appearance |

Colorless to pale yellow transparent liquid |

|

Density |

0.925 g/cm³ @ 25°C |

|

Melting Point |

–66°C |

|

Boiling Point |

115–117°C |

|

Vapor Pressure |

~1.6 kPa @ 20°C |

|

Flash Point |

26°C (closed cup) |

|

Solubility |

Miscible with water, alcohols, ethers; good solubility in organic solvents |

Volatile and flammable. Avoid ignition sources and handle in well-ventilated areas.

Absorbs moisture from air. Store under dry nitrogen or inert gas to maintain purity.

Stable in stainless steel or HDPE containers. Avoid long exposure to acids or oxidizers.

Stable under recommended storage temperatures (5–30°C); slight degradation above 100°C.

Our technical team is available to provide detailed specifications, safety information, and handling guidelines for our 4-methylmorpholine products.

Rigorous Testing and Strict Quality Management for Consistent Excellence

Each batch of incoming raw materials undergoes rigorous testing to verify purity and compliance with specifications before entering production.

Continuous monitoring throughout the production process with real-time analytics to ensure consistency and detect any deviations immediately.

Comprehensive analysis of each production batch against all specified parameters using advanced analytical techniques.

Application-specific testing to verify product performance in simulated customer processes, ensuring it meets real-world requirements.

Comprehensive documentation package including Certificate of Analysis, traceability records, and quality assurance documentation.

Our quality management system is certified to ISO 9001:2015, ensuring consistent processes and continuous improvement.

Environmental management certification demonstrating our commitment to sustainable manufacturing practices.

Occupational Health and Safety Management System certification for safe handling of hazardous materials.

Compliant with European Union's Registration, Evaluation, Authorization and Restriction of Chemicals regulation.

Our dedicated quality control laboratory is equipped with advanced analytical instruments to ensure the highest standards of product quality and consistency:

For precise determination of 4-Methylmorpholine (NMMO) purity and impurity profiles

For precise determination of 4-Methylmorpholine N-oxide (NMMO) purity and impurity profiles

For moisture content analysis with high sensitivity

For structural verification and identification of functional groups

To ensure consistent particle distribution in solid NMMO formulations (if applicable)

We partner with our customers to ensure our products meet their specific quality requirements through our comprehensive quality assurance program:

We develop custom specifications to match your unique process requirements.

Tailored quality standards are provided based on your end-use application.

We offer formulation flexibility to meet specialized technical demands.

Each product is adjusted to ensure compatibility with your production line.

Regulatory and safety parameters are aligned with your regional compliance.

Regulatory and safety parameters are aligned with your regional compliance.

Still have questions? Here are the most common queries buyers ask when sourcing high-purity 4-Methylmorpholine.

Our standard MOQ is 100 kg, but we also support flexible trial orders starting from 25 kg or even smaller upon request.

Yes, we offer free samples (100–500g) for quality evaluation, with express delivery and complete COA/MSDS documentation.

Absolutely. We can tailor purity (≥99.0%) and moisture specs, and offer packaging in HDPE drums, steel cylinders, or amber bottles according to your usage and local regulations.

Yes. It is classified as flammable (UN 2252) under ADR/IMDG/IATA standards. We offer UN-compliant packaging and documentation for safe and legal international shipping.

Our product is produced in ISO 9001 / GMP-compliant facilities. We provide complete regulatory support including COA, MSDS, TDS, REACH, Certificate of Origin, and more.

Store in tightly sealed containers under inert atmosphere in a cool, dry, and well-ventilated area. Keep away from moisture, acids, and ignition sources.

We maintain regular stock for fast dispatch. Orders are typically shipped within 3–5 working days via sea, air, or courier depending on volume and destination.

Yes. Our technical team provides guidance for handling, formulation compatibility, process safety, and documentation needed for local registrations.

TUODA stands out with strict batch consistency, ≥99.0% purity, low moisture control, and strong customization service backed by over 10 years of global export experience in fine chemicals.

Can’t find your question here? Our team is ready to assist you 1-on-1.

Explore related catalysts and fine chemical intermediates available from TUODA.

CAS:96-10-6

CAS:563-43-9

CAS:12075-68-2

CAS:1191-15-7

CAS:100-99-2

CAS:35794-11-7

Contact us today to receive a free quote and expert consultation on chemical intermediates and petrochemical solutions. Tuoda is ready to provide the perfect solution for your project.

At Tuoda, we transform complexity into simplicity! Follow these 3 easy steps to get started today:

Share your requirements, and we will give you clear details on the quality, price, payment terms, packaging, and delivery time for our chemical solutions, helping you plan your procurement. A customized quote will be provided within 24 hours.

Once you approve the details and provide the deposit, we’ll begin mass production and handle all the logistics to ensure smooth delivery.

Our commitment is to deliver high-quality, reliable chemical products on time, helping you meet your production goals.

WhatsApp us

Have a question or need a quote? Fill out the form below, and our team will get back to you as soon as possible!

TUODA Chemical Support

Technical Support

TUODA Chemical Support

Hello, this is TUODA. How can we assist you today?